How do you make lead tetroxide? Red Lead or Minium

Chemical Formula

- Red Lead – Pb3O4

- Lead Monoxide – PbO

Lead nitrate: Pb(NO3)2

- Sodium carbonate: Na2CO3

- Sodium plumbite – Na2PbO2

Dihydrogen tetrachloropalladate: H2[PbCl4]

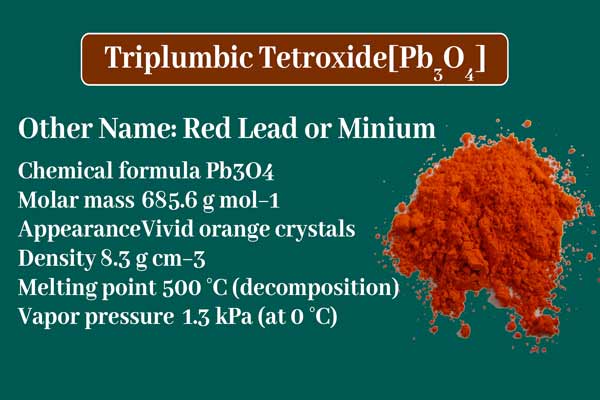

Tri-plumbic Tetraoxide

It is also called Red Lead or sindoor or sis sindoor or minium.

What is the formula of red lead?

Red Lead formula: Pb3O4

Preparation of Red Lead

Red lead is obtained by heating lead or lead mono oxide or litharge to about 450°C.

6Pb + 3O2 → 6PbO

6PbO + O2 → 2Pb3O4

Properties of Red Lead

Physical Properties

It is red powder. Which does not dissolve in water.

Chemical Properties

Effect of heat: On heating more, it decomposes into litharge and oxygen gas.

2Pb3O4 → 6PbO + O2

Reaction with dilute nitric acid: Reaction of lead dioxide is obtained by the reaction of dilute nitric acid and red lead and the residue of lead nitrate remains.

Pb3O4 + 4HNO3 → 2Pb(NO3)2 + 2H2O + PbO2

Reaction with concentrated sulfuric acid: Oxygen gas is produced by the reaction of concentrated sulfuric acid.

2Pb3O4 + 6H2SO → 6H2O + 6PbSO4 + O2

Reaction with concentrated hydrochloric acid: Reaction with concentrated hydrochloric acid produces chlorine gas.

Pb3O4 + 8HCl → 4H2O + 3PbCl2 + Cl2

Red Lead Uses

- Used to make matches.

- Used to making Red pencil.

- Used in glass factories.

- Used to making colors.

- Used to make Plumbers cement connecting gas taps.

Basic Lead Carbonate

It is also called white lead or white.

2PbCO3.Pb(OH)2

When added to lead nitrate solution with sodium carbonate or potassium carbonate solution, white lead with Sodium nitrate is obtained.

Preparation of White Lead

On the industrial scale, it is prepared by the following two methods.

Dutch Process

Carter Process

Dutch Process

Dung, droppings, tree bark, leather shavings, etc. are spread on the floor of the room. They contain carbon dioxide gas.

Put aludels in queues on it. aludels are clay pots. In which lead holes and round plates are kept. Their narrow part is filled with acetic acid.

They are covered with wooden planks. They again lay dung, droppings, bark of trees, peeling of leather, etc. on them. In this way, many layers fill the room to the ceiling.

When the room is closed and opened after about two months, lead lead is found in the lead plates. Dry it by scrapping and washing it with water.

Chemical reaction:

2Pb + 2CH3COOH + O2 → Pb(CH3COO)2.Pb(OH)2

Basic Lead Acetate reacts with carbon dioxide and moisture obtained by fermentation to form white lead.

3 Pb(CH3COO)2.Pb(OH)2 + 4CO2 + 2H2O → 2[2PbCO3.Pb(OH)2] + 6CH3COOH

This method gives the best quality white.

Carter Process

This is the German method. Safeda is obtained within 15 days by this method.

In this method, large cylindrical casks of wood are used which rotate in a horizontal position. Melt lead is filled inside these pipes.

When they are moving, the mixture of carbon dioxide and air flows in them at a fast speed. On doing this, the melt lead splits into smaller particles. The drops of acetic acid are dripping from the top.

Small particles of lead, carbon dioxide gas, combine with air and acetic acid to make white.

This is the modern method of making white Lead.

Properties of White Lead

Physical Properties

It is a solid crystal-free solid material of white color. It does not dissolve in water. It dissolves in ammonia acetate. It also dissolves easily in linseed oil. It is also highly toxic.

Chemical Properties

It forms lead sulfide in the presence of hydrogen sulfide, which is black in color. Due to this demerit, its use as a paint has reduced. Nowadays, lithopone, which is a mixture of BaSO4 ZnS and ZnO, is used in its place. It is not blackened by H2S.

Uses of White Lead

Most commonly used as white paint.

It is used in making thickeners and pigments.

In the business of making utensils, it is used to make it shine and varnish.