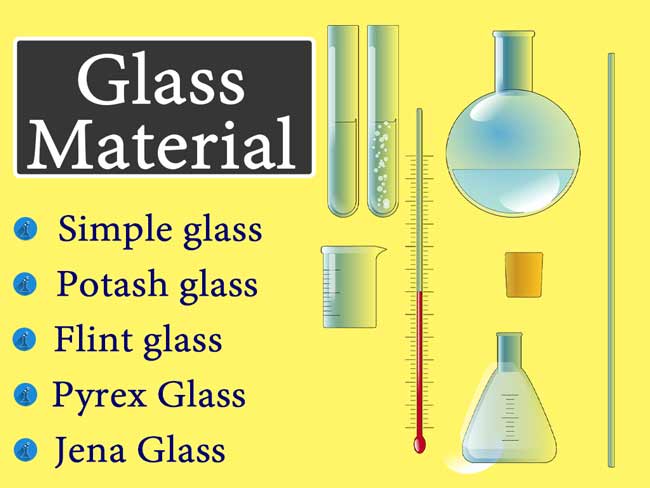

Glass Material | Composition, Types of Glass, How to make colored glass?

Glass Material – Glass is a mixture of silica and metallic silicates, these metallic silicates must contain an alkali metal silicate. There are some characters of this Glass mixture.

· Homogeneous

· Transparent

· Crystal

Thus many mixtures of silica and metallic silicates can be made.

Example:

1) Sodium silicate, Calcium silicate, Mixture of silica

2) Potassium silicate, Calcium silicate, Mixture of silica

Therefore, different types of glass can be made. Some of the main types of glass are their average compositions, the initial materials used in their making and their major uses are given below.

Types of Glass

Simple Glass

Mixture: Na2SiO3. CaSiO3.4SiO2.

Use Matters: Sodium Carbonate (Na2CO3), Calcium Carbonate (CaCO3) and Silica (SiO2)

Uses: Electric tube, cheap lab equipment, windows glass for making simple utensils.

Hard Glass or Potash Glass

Mixture: K2SiO3. CaSiO3. 4SiO2.

Use Matters: Potassium Carbonate (K2CO3), Calcium Carbonate (CaCO3) and Silica (SiO2)

Uses: In making high temperature heated glass equipment in the laboratory.

Flint Glass

Mixture: K2SiO3. PbSiO3. 4SiO2.

Use Matters: Potassium Carbonate (K2CO3), lead carbonate (PbCO3), Red lead (Pb3O4) and Silica (SiO2)

Uses: In making lenses of cameras and binoculars etc., electric bulbs. And in making other optical instruments

Pyrex Glass

Mixture: Na3BO3. Na2SiO3. AlBO3. Al2SiO5. 4SiO2.

Use Matter: Sodium Borate (Na3BO3), Sodium Carbonate (Na2CO3), Aluminium borate (AlBO3), Aluminium oxide (Al2O3) and Silica (SiO2)

Uses: Making high quality glass equipment

Jena Glass

Mixture: Zn3(BO3)2. ZnSiO3. Ba3(BO3)2. Ba2SiO3. 4SiO2.

Use Matters: Zinc Borate (Zn3(BO3)2), Zinc oxide (ZnO), Barium Borate (Ba3(BO3)2), Barium oxide (BaO) and Silica (SiO2)

Uses: Making high quality glass equipment

Glass Material Composition

Glass is not a compound, it is a mixture, so it has no molecular formula.

Some of the main substances used for the raw materials used for making glass are

- Sand, sand quartz or flint pieces SiO2

- Marble, chalk or limestone CaCO3

- Boric acid H3BO3

- Soda Ash Na2CO3

- Sodium sulphate and carbon mixture

- Red lead Pb3O4

Crux glass are used as glass optical filters. When light rays pass through it, it stops ultraviolet rays. For this reason it is used in making eyeglass lenses. Cerium oxide CeO2 is used to make crux glass.

To make any type of glass, first of all, the above mentioned initial substances are grinded by taking them in proper proportion. And thus get a fine powder.

Heats this fine powder in a furnace at 1200°C to 1500°C heat. Siemens-Martin’s open bottom furnace or any other similar furnace is used to manufacture glass.

This furnace is heated by producer gas and the regenerative system is fully utilized. At high temperature of furnace, metallic salts present in primary materials react with silica to form metallic silicates.

The following reactions take place when the primary materials used in making ordinary glass are mixed and heated in the appropriate proportion.

Na2CO3 + SiO2 → Na2SiO3 + CO2

CaCO3 + SiO → CaSiO3 + CO2

Na2SiO3 + CaSiO3 + 4SiO2 → Na2SiO3.CaSiO3.4SiO2

The mixture obtained as a result of the reactions remains in a liquid state at high temperature of the furnace. It is cooled to about 800°C and mold into moulds.

Slowly cooling the mild in the moulds at ordinary temperature makes the glass apparatus ready. This is why glass is considered a super cooled liquid.

Annealing of Glass

Glass is in the form of a soft paste at about 800. The equipment prepared when molding it in molds is very hot. Since hot glass utensils tend to shrink faster than the inside when cooled, the hot glass utensils break quickly if they are cooled quickly.

For this reason, hot glass utensils are slowly cooled in special types of pot furnaces. This action is called glass annealing.

Making Colored Glass

To make colored glass, a small amount of suitable colored material is added to the mixture of preparatory materials used in the manufacture of glass. The glass obtained in this condition is colored. The following are some of the materials used to make glass colored.

| Colors | Matters that make Glass Colored |

|---|---|

| Yellow | Ferric salt (Fe3+), potassium dichromate (K2Cr2O7), cadmium sulphide (CdS) |

| Green | Ferrous salt (Fe2+), chromium salt (Cr3+) |

| Blue | Cupric salts (Cu2+) and cobalt oxide (CoO) |

| Red | cuprous salt (Cu+) |

| Orange | Antimony trisulfide (Sb2S3) and selenium (Se) |

| Purple | Manganese dioxide (MnO2) |

Glass Material Facts

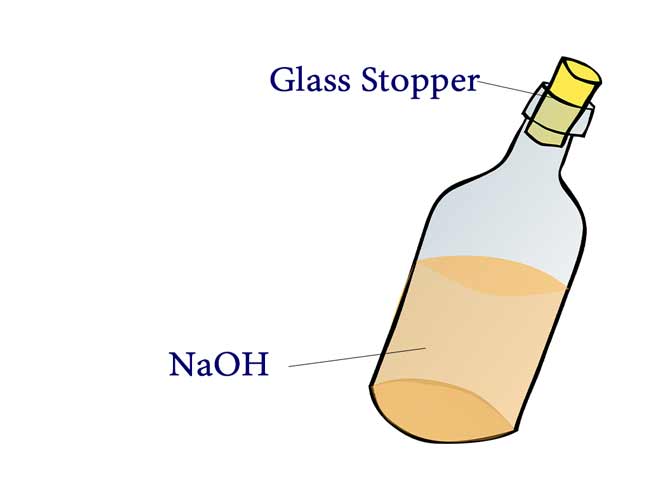

Do not apply glass stopper in aqueous solution bottle of NaOH. The reason for this is that NaOH reacts with SiO2 present in glass to form sodium silicate.

2NaOH + SiO2 → Na2SiO3 + H2O

The glass stopper becomes jam due to glass being formed between the glass stopper and the wall of the bottle. The glass stopper jammed can also be explained in this way.

The structure of silicates depends on the following structural unit.

Due to the bonding on both sides, the glass stopper and the middle glass in the glass wall are joined on both sides and the glass stopper becomes jam.

Do not put HF in a glass bottle. The reason for this is that HF reacts with the glass substance.

SiO2 + 4HF → SiF4 + 2H2O

Na2SiO3 + 6HF → Na2SiF6 + 3H2O

CaSiO3 + 6HF → CaSiF6 + 3H2O

Due to the above reaction, HF is used to etching of glass and write on the glass.

Glass industry in India

The art of making glass bangles was in India since ancient times. A 2500-year-old piece of glass has been found in a village called Kopia in Basti district in Uttar Pradesh.

Firozabad glass bangles located in Uttar Pradesh are famous for their high variety all over the world. Apart from bangles, scientific instruments, beads of garlands, fake beads, glass sheets, glass bulbs, electric road, are also made.

Glass factories in India are the highest in Uttar Pradesh. Apart from Uttar Pradesh, glass factories are also located in West Bengal and Maharashtra. According to the Five Year Plan, glass industry is increasing day by day in India.